Chemistry Thursday: More about the impact of the melting point of triglycerides the melting point of cocoa and shea butters that we can use to make awesome products, part 44

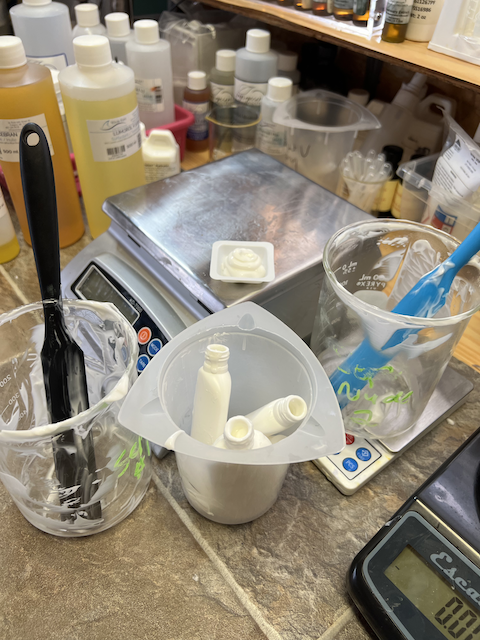

Let’s continue our investigation into triglycerides in part 44 by looking at the melting points of various forms of triglycerides in butters, before getting to our fun experiment about the heating and cooling of said butters to see how the way we formulate with them affects their physical properties and sensory characteristics that I’ll be...